Fluoroelastomers are a class of synthetic rubber which provides extraordinary levels of resistance to chemicals, oil, and heat while providing useful service life above 200°C. The outstanding heat stability and excellent oil resistance of these materials are due to the high ratio of fluorine to hydrogen, the strength of the carbon-fluorine bond, and the absence of unsaturation. Fluoroelastomers are referred to generically as FKM polymers per the nomenclature noted in ASTM D1418.

In the SAE J200 / ASTM D2000 classification system for rubber materials, fluoroelastomers are documented as an “HK” material and can be found in the HK section of this specification.

The original fluoroelastomer was a copolymer of hexafluoropropylene (HFP) and vinylidene fluoride (VF2). It was developed by the DuPont Company in 1957 in response to high-performance sealing needs in the aerospace industry. To provide even greater thermal stability and solvent resistance, tetrafluoroethylene (TFE) containing fluoroelastomer terpolymers were introduced in 1959 and in the mid to late 1960’s lower viscosity versions of FKMs were introduced.

A breakthrough in crosslinking occurred with the introduction of the bisphenol cure system in the 1970’s. This bisphenol cure system offered much-improved heat and compression set resistance with better scorch safety and faster cure speed. In the late 70’s and early 80’s fluoroelastomers with improved low-temperature flexibility were introduced by using perfluoro methyl vinyl ether (PMVE) in place of HFP. These polymers require a peroxide cure. The latest FKM polymers have a much broader fluids resistance profile than standard fluoroelastomers and are able to withstand strong bases and ketones as well as aromatic hydrocarbons, oils, acids, and steam.

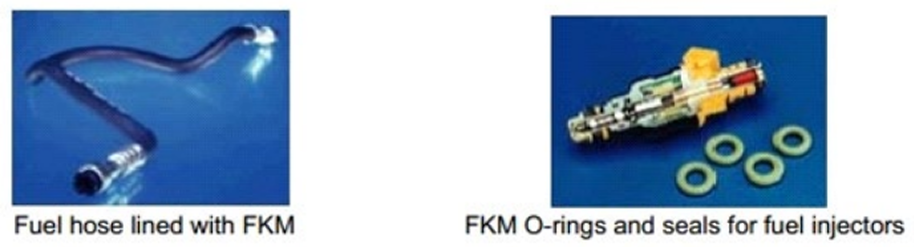

Fluoroelastomers are used in a wide variety of high-performance applications. FKM provides premium, long-term reliability even in harsh environments. A partial listing of current end-use applications include:

| Aerospace | Automotive | Industrial |

|---|---|---|

| O-ring seals in fuels, lubricants, & hydraulic systems | Shaft Seals | Hydraulic o-ring seals |

| Manifold gaskets | Valve stem seals | Check valve balls |

| Fuel tank bladders | Fuel Injector O-rings | Military flare binders |

| Fuel hoses | Diaphragms | |

| Engine lube siphon hose | In-tank and quick connect fuel system seals | Electrical connectors |

| Clips for jet engines | Gaskets (valve & manifold) | Flue duct exp. joints |

| Tire valve stem seals | Balls for check valves | Valve liners |

| Lathe cut gaskets | Roll covers | |

| Sheet stock/cut gaskets |

Fluoroelastomers are a family of fluoropolymer rubbers, not a single entity. Fluoroelastomers can be classified by their fluorine content, 66%, 68%, & 70% respectively. Fluoroelastomers having higher fluorine content have increasing fluids resistance derived from increasing fluorine levels. Peroxide cured fluoroelastomers have inherently better water, steam, and acid resistance.

Since one of the primary attributes of fluoroelastomers is its fluids resistance, it is necessary to define the capability of each type of FKM to various environments.

Fluid or Environment |

Type of Fluoroelastomers (a) | |||||||

|---|---|---|---|---|---|---|---|---|

| A 66% fluorine copolymer |

B 68% fluorine copolymer |

F 70% fluorine terpolymer |

GBL 66% fluorine terpolymer |

GF 70% fluorine terpolymer |

GLT 64% fluorine low temp. terpolymer |

GFLT 67% fluorine low temp. terpolymer |

ETP 67% fluorine non-VF2 terpolymer |

|

| Cure System | ||||||||

| Bisphenol | Peroxide | |||||||

| Aliphatic Hydrocarbons, Process fluids, chemicals | 1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

| Aromatic Hydrocarbons (toluene, etc.), Process fluids, chemicals |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| Automotive & Aviation Fuels - (pure hydrocarbons - no alcohol) |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

| Automotive fuels containing legal levels (5-15%) of alcohols & ethers (methanol, ethanol, MTBE, TAME) |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

| Bisphenol | Peroxide | |||||||

| Automotive / methanol fuels blends up to 100% methanol (flex fuels) |

NR |

2 |

1 |

2 |

1 |

NR |

1 |

1 |

| Engine lubricating oils (SE-SF grades) |

2 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

| Engine lubricating oils (SG-SH grades) |

3 |

2 |

2 |

1 |

1 |

1 |

1 |

1 |

| Acid (H2SO4, HNO3), hot water, and steam | 3 |

2 |

2 |

1 |

1 |

1 |

1 |

1 |

| Strong base, high pH, caustic, amines | NR |

NR |

NR |

NR |

NR |

NR |

NR |

1-2 |

| Low molecular weight carbonyls - 100% concentration (MTBE, MEK, etc.) |

NR |

NR |

NR |

NR |

NR |

NR |

NR |

1-2 |

| Low temperature sealing capability TR-10 test results | -17°C |

-14°C |

-7°C |

-15°C |

-6°C |

-30°C |

-24°C |

-11°C |

Fluoroelastomers are generally made by an emulsion polymerization process. Fluoro-monomers such as HFP, VF2, and TFE are fed to a reactor under elevated temperature and pressure along with surfactants and other additives. Once the polymerization is complete the latex is removed, the polymer coagulated and washed, and the polymer is dried and packaged for use.

The main fluoroelastomer compositions are shown below:

Copolymer fluoroelastomer: -(CF2-CF)-(CH2-CF2) - CF3

Terpolymer fluoroelastomer: -(CF2-CF)-(CH2-CF2)-(CF2-CF2) - TFE level can be varied for different fluorine contents CF3

Improved Low Temperature Fluoroelastomer Terpolymer: -(CF2-CF)-(CH2-CF2)-(CF2-CF2) - HFP replaced with fluoro-ether O-CF3

Non-VF2 Fluoroelastomer Terpolymer: -(CF2-CF)-(CH2-CH2 )-(CF2-CF2) - VF2 replaced with ethylene, imparts base /amine resistance O-CF3

Fluoroelastomers are a high value in use class of synthetic rubber which provides extraordinary levels of resistance to chemicals, oil and heat, and service life above 200°C. Fluoroelastomers can be fabricated into seals, O-rings, and hoses for a variety of high-performance applications in the automotive, aerospace, and petrochemical industries.

Building a Sutainable Future for Your Organization and the Synthetic Rubber Industry

Download here

Address:

16360 Park Ten Place Suite 110

Houston, TX 77084

Contact Us:

+1 713 783 1703

info@iisrp.com