Ethylene-propylene rubbers & elastomers (also called EPDM and EPM) continue to be one of the most widely used and fastest growing synthetic rubbers having both specialty and general-purpose applications.

Polymerization and catalyst technologies in use today provide the ability to design polymers to meet specific and demanding application and processing needs. Versatility in polymer design and performance has resulted in broad usage in automotive weather-stripping and seals, glass-run channel, radiator, garden and appliance hose, tubing, belts, electrical insulation, roofing membrane, rubber mechanical goods, plastic impact modification, thermoplastic vulcanizates and motor oil additive applications.

Heat aging resistance up to 130°C can be obtained with properly selected sulfur acceleration systems and heat resistance at160°C can be obtained with peroxide cured compounds. Compression set resistance is good, particularly at high temperatures, if the sulfur donor or peroxide cure systems are used.

Ethylene-propylene rubbers are valuable for their excellent resistance to heat, oxidation, ozone and weather aging due to their stable, saturated polymer backbone structure. Properly pigmented black and non-black compounds are color stable. As non-polar elastomers, they have good electrical resistivity, as well as resistance to polar solvents, such as water, acids, alkalies, phosphate esters and many ketones and alcohols. Amorphous or low crystalline grades have excellent low-temperature flexibility with glass transition points of about minus 60°C.

These polymers respond well to high filler and plasticizer loading, providing economical compounds. They can develop high tensile and tear properties, excellent abrasion resistance, as well as improved oil swell resistance and flame retardance. A general summary of properties is shown in Table 1 below.

| Polymer Properties | Mooney Viscosity, ML 1+4 @ 125°C | 5-200+ |

| Ethylene Content, wt % | 45 to 80 wt. % | |

| Diene Content, wt. % | 0 to 15 wt. % | |

| Specific Gravity, gm/ml | 0.855-0.88 (depending on polymer composition) | |

| Vulcanizate Properties* | Hardness, Shore A Durometer | 30A to 95A |

| Tensile Strength, MPa | 7 to 21 | |

| Elongation, % | 100 to 600 | |

| Compression Set B, % | 20 to 60 | |

| Vulcanizate Properties* Continued... | Useful Temperature Range, °C | -50° to +160° |

| Tear Resistance | Fair to Good | |

| Abrasion Resistance | Good to Excellent | |

| Resilience | Fair to Good (stable over wide temp. ranges) |

Ethylene-propylene rubbers use the same chemical building blocks or monomers as polyethylene (PE) and polypropylene (PP) thermoplastic polymers. This ethylene (C2) and propylene (C3) monomers are combined in a random manner to produce rubbery and stable polymers. A wide family of ethylene-propylene elastomers can be produced ranging from amorphous, non-crystalline to semi-crystalline structures depending on polymer composition and how the monomers are combined. These polymers are also produced in an exceptionally wide range of Mooney viscosities (or molecular weights).

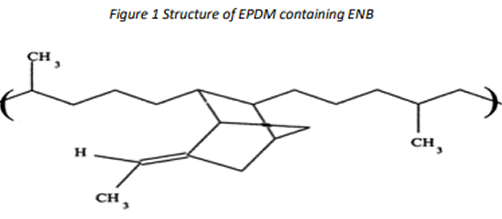

The ethylene and propylene monomers combine to form a chemically saturated, stable polymer backbone providing excellent heat, oxidation, ozone and weather aging. A third, non-conjugated diene monomer can be ter-polymerized in a controlled manner to maintain a saturated backbone and place the reactive unsaturation in a side chain available for vulcanization or polymer modification chemistry. The terpolymers are referred to as EPDM (or ethylene-propylene-diene with “M” referring to the saturated backbone structure). An EPDM polymer structure is illustrated in Figure 4. The ethylene-propylene copolymers are called EPM.

The two most widely used diene ter-monomers are primarily ethylidene norbornene (ENB) followed by dicyclopentadiene (DCPD). Each diene incorporates with a different tendency for introducing long-chain branching (LCB) or polymer side chains that influence processing and rates of vulcanization by sulfur or peroxide cures. These characteristics are summarized in Table 2.

| Ter-monomer | Cure & Property Features | Long Chain Branching |

|---|---|---|

| ENB | Fastest and Highest State of Cure | Low to Moderate |

| Good Tensile | ||

| Good Compression Set Resistance | ||

| s | ||

| DCPD | Slow Sulfur Cure | High |

| Good Compression Set Resistance | Stabilizer |

Specialized catalysts are used to polymerize the monomers into controlled polymer structures. Since their introduction, ethylene-propylene elastomers have used a family of catalysts referred to as Zeigler-Natta named after their initial developers. Improvements in catalysts and processes have provided increased productivity while maintaining control of polymer structure. Most recently a new family of catalysts, referred to as metallocene catalysts, has been developed and are in commercial use.

The solution polymerization process is the most widely used and is highly versatile in making a wide range of polymers. Ethylene, propylene, and catalyst systems are polymerized in an excess of hydrocarbon solvent. Stabilizers and oils, if used, are added directly after polymerization. The solvent and unreacted monomers are then flashed off with hot water or steam, or with mechanical devolatilization. The polymer, which is in crumb form, is dried with dewatering in screens, mechanical presses or drying ovens. The crumb is formed into wrapped bales or extruded into pellets. The high viscosity, crystalline polymers are sold in loosely compacted, friable bales or as pellets. The amorphous polymers grades are typically in solid bales.

There are three major commercial processes, solution, slurry (suspension) and gas-phase, for manufacturing ethylene propylene rubbers. The manufacturing systems vary with each of the several producers. There are differences in the product grade slates made by each producer and process, but all are capable of making a variety of EPDM and EPM polymers. The physical forms range from solid to friable bales, pellets and granular forms and oil blends.

The slurry (or suspension) process is a modification of bulk polymerization. The monomers and catalyst system are injected into the reactor filled with propylene. The polymerization takes place immediately, forming crumbs of polymer that are not soluble in the propylene. Slurry polymerization reduces the need for solvent and solvent handling equipment, and the low viscosity of the slurry helps to control temperature and handle the product. The process is not limited by solution viscosity, so high molecular weight polymer can be produced without a production penalty. Flashing off the propylene and ter-monomer completes the process before forming and packaging.

Gas-phase polymerization technology was recently developed for the manufacture of ethylene-propylene rubbers. The reactor consists of a vertical fluidized bed. Monomers and nitrogen in gas form along with catalyst are fed to the reactor and solid product is removed periodically. The heat of reaction is removed through the use of the circulating gas that also serves to fluidize the polymer bed. Solvents are not used eliminating the need for solvent stripping, washing, and drying. The process is also not limited by solution viscosity, so high molecular weight polymer can be produced without a productivity penalty.

Continuous injection of a substantial amount of carbon black used as a partitioning aid is necessary to prevent the polymer granules sticking to each other and to reactor walls. Products are made in a granular form to enable rapid mixing.

The processing, vulcanization and physical properties of ethylene-propylene elastomers are largely controlled by the characteristics of ethylene content, diene content, molecular weight (or Mooney viscosity) and molecular weight distribution. For example, decreasing ethylene content decreases crystallinity and associated properties such as hardness and modulus.

General polymer features in rubber compounding are summarized in Table 3.

| Characteristics | High | Low |

|---|---|---|

| Ethylene Content | Good Green Strength | Fast Mixing |

| Flow at High Extrusion Temperatures | Low-Temperature Flexibility | |

| High Tensile Strength, Modulus | Low Hardness and Modulus | |

| s | High Loading (Reduced Cost) | Calendering and Milling |

| Diene Content | Cure Degree and Fast Rate | Scorch Resistance |

| Acceleration Versatility | High Heat Stability | |

| Good Compression Set | Low Hardness and Modulus | |

| High Modulus, Low Se | ||

| Molecular Weight Good Tensile | Tear | Modulus |

| High Loading and Oil Extension High Extrusion Rates | High Loading and Oil Extension High Extrusion Rates | |

| Good Green Strength | Good Calendering | |

| Collapse Resistance | Low Viscosity, Scorch Resistance | |

| MWD | Extrusion Feed and Smoothness | Fast Extrusion Rate |

| Collapse Resistance | High Cure | |

| Good Calendering and Milling | Good Physicals |

thylene-propylene elastomers are one of the most versatile, fastest growing and interesting synthetic rubber polymers. Excellent resistance to heat, oxidation, ozone and weather aging are expected to provide continued value in demanding automotive, construction, and mechanical goods applications. Current and emerging advanced polymerization and catalyst technologies also provide the ability to design polymers to meet application and processing needs that are important to meeting the ever increasing demands for product quality, uniformity, and performance.

Building a Sutainable Future for Your Organization and the Synthetic Rubber Industry

Download here

Address:

16360 Park Ten Place Suite 110

Houston, TX 77084

Contact Us:

+1 713 783 1703

info@iisrp.com